| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : OEM

Model Number : HDPE Plastic Geocell

Certification : ISO certificate

Place of Origin : China

MOQ : 1000 square meters

Price : USD0.68-USD2.16 per square meter

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 60, 000 Square Meters Per Day

Delivery Time : 7-10 working days

Packaging Details : Standard Port Packing or According to Customer′s Requirements

hdpe geocell Feature : Corrosion Resistant, Oxidation Resistance, Chemical Stability, Wear-resistant

Application : Landfill, fish pond, lake, etc,, Road Basement

Thickness : 1.5 or 1.6 or 1.7mm

After-sales Service : Support for Quality Traceability

Surface : Textured Smooth

color : Black, Green, Sand

Filler : Concrete Materials, Soil & Rock

Welding Distance : 300mm-1000mm

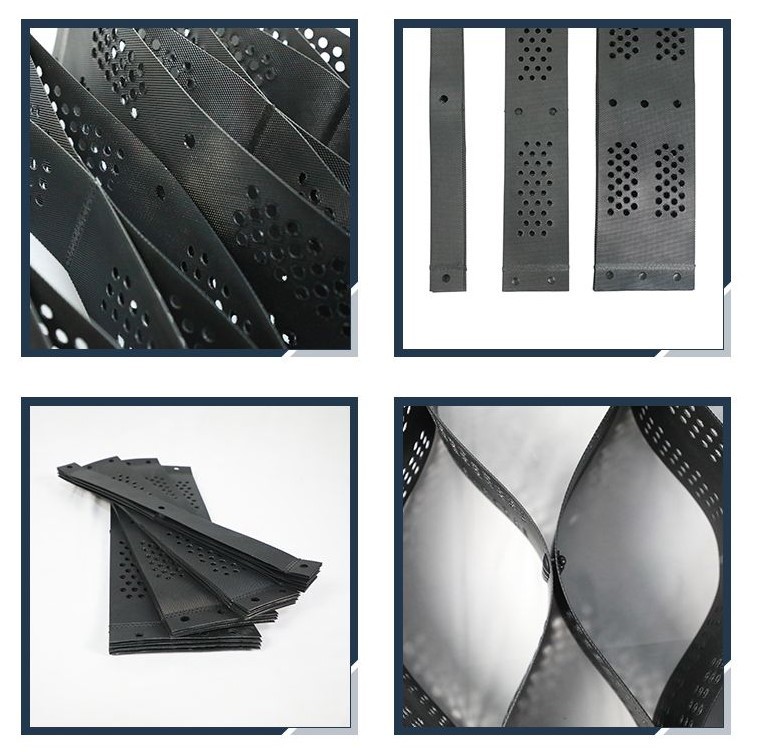

Textured and Perforated HDPE Plastic Geo cell system manufacturer price gravel grid Geoweb for road construction

gravel grid Geoweb Description:

HDPE geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique. It is flexible to fold during the transport and installation on construction site. The geocell nets will be filled with soils, granular, cements or other on-site infill materials when stretched into web structures, which has powerful and rigid confinement in the lateral and vertical sides.

HDPE plastic honeycomb hdpe geocell gravel grid Specifications:

1.Cell depth: 50mm , 100mm , 150mm , 200mm , 250mm

2. Welding space: 330mm~1600mm

3. Thickness: 1.0mm , 1.2mm , 1.5mm , 1.8mm

4. Appearance: smooth / textured

Benefits of the Geocell Confinement System:

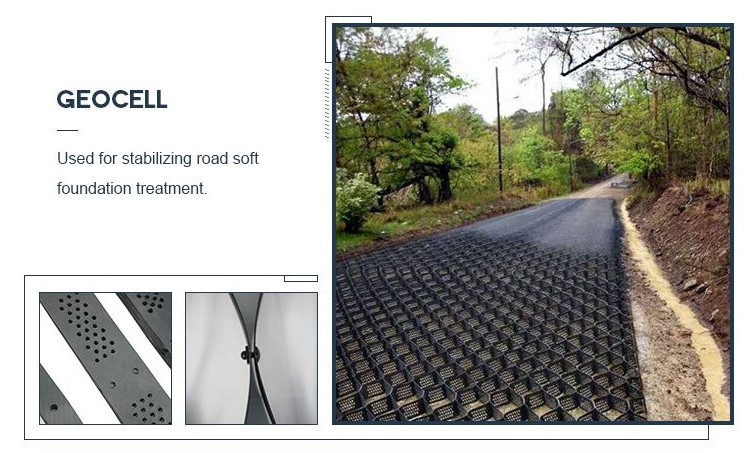

1). Reduce Fill Required – With the use of Geocell, fill quantity can be reduced by up to 70% while maintaining or improving bearing capacity. This saves time, transport, and material costs.

2). Eliminate Rutting – Prevent the lateral movement of infill. Lower quality fill materials can often be used since they are contained within the cells.

3). Support Heavy Loads – Improve the bearing capacity of subgrade soils and extend the life-cycle of the road.

4). Quick & Simple Installation - Easily installed without specialized equipment or crews.

5). Utilize Local Fill – Most local soils can be used as fill minimizing transportation costs and installation time.

6). Perforated Cells – Allow water to drain freely through permeable aggregates.

| Material Properties | Unit | Test Method | |||||

| Cell Depth | mm | 75 | 100 | 150 | 200 | ||

| Polymer Density | g/cm3 | 0.935-0.965 | ASTM D 1505 | ||||

| Environmental Stress Crack Resistance | Hours | >400 | ASTM D 5397 | ||||

| Environmental Stress Crack Resistance | Hours | 6000 | ASTM D 1693 | ||||

| Carbon Black Content | % | 1.5% - 2.0% | ASTM D 1603 | ||||

| Nominal Sheet Thickness Before Texturing | mm | 1.27 -5%,+10% | ASTM D 5199 | ||||

| Nominal Sheet Thickness After Texturing | mm | 1.52-5%,+10% | ASTM D 5199 | ||||

| Strip Puncture Resistance | N | 450 | ASTM D 4833 | ||||

| Seam Peel Strength | N | 1065 | 1420 | 2130 | 2840 | EN ISO13426-1B | |

| Seam Efficiency | % | 100 | GRI-GS13 | ||||

| Nominal Expanded Cell Size (width x length) | mm | 320x287,475x508 etc | |||||

| Nominal Expanded Panel Size (width x length) | m | 2.56x8.35, 4.5x5.0, 6.5x4.5, 6.1x2.44 | |||||

Applications:

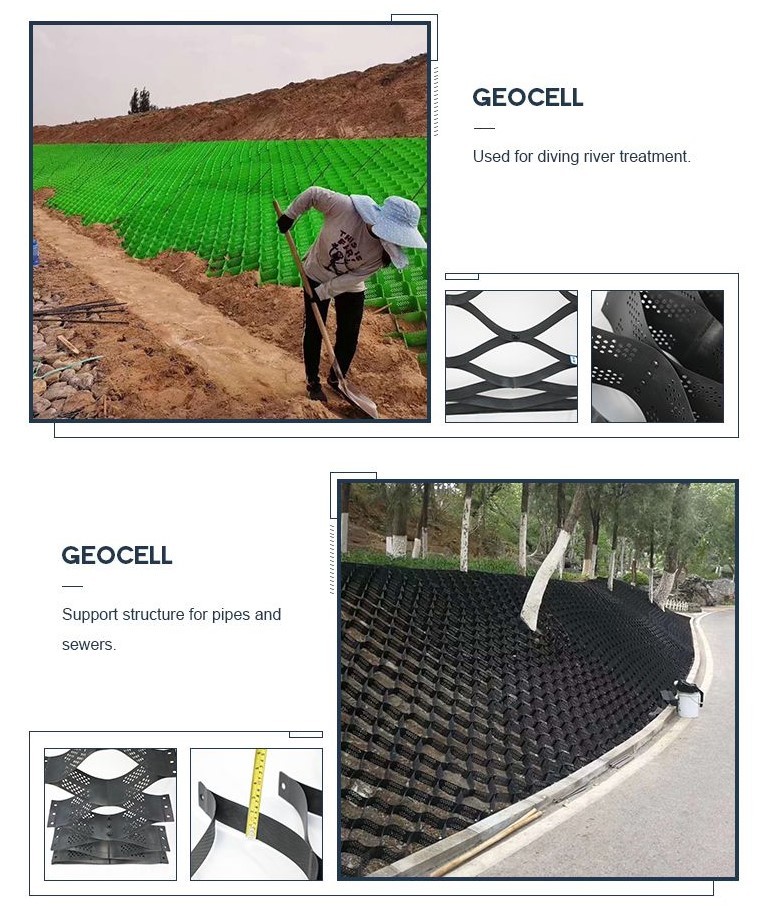

Plastic geocell grid gravel for road

1. Used for all kinds of road building , driveways , soil stabilization and embankment stabilization

2. Used to stabilize river embankments .

3. Used to prevent landslides .

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed , construction speed , good performance and greatly reduce the project cost .

|

|

Textured Perforated HDPE Geocell Plastic Geo Cell Geoweb Erosion Control System Images |